INNOMAC PASSENGER CUM MATERIAL HOIST

Passenger Hoist in BangalorePassenger Hoist in BangalorePassenger Hoist in BangalorePassenger Hoist in BangalorePassenger Hoist in BangalorePassenger Hoist in Bangalore

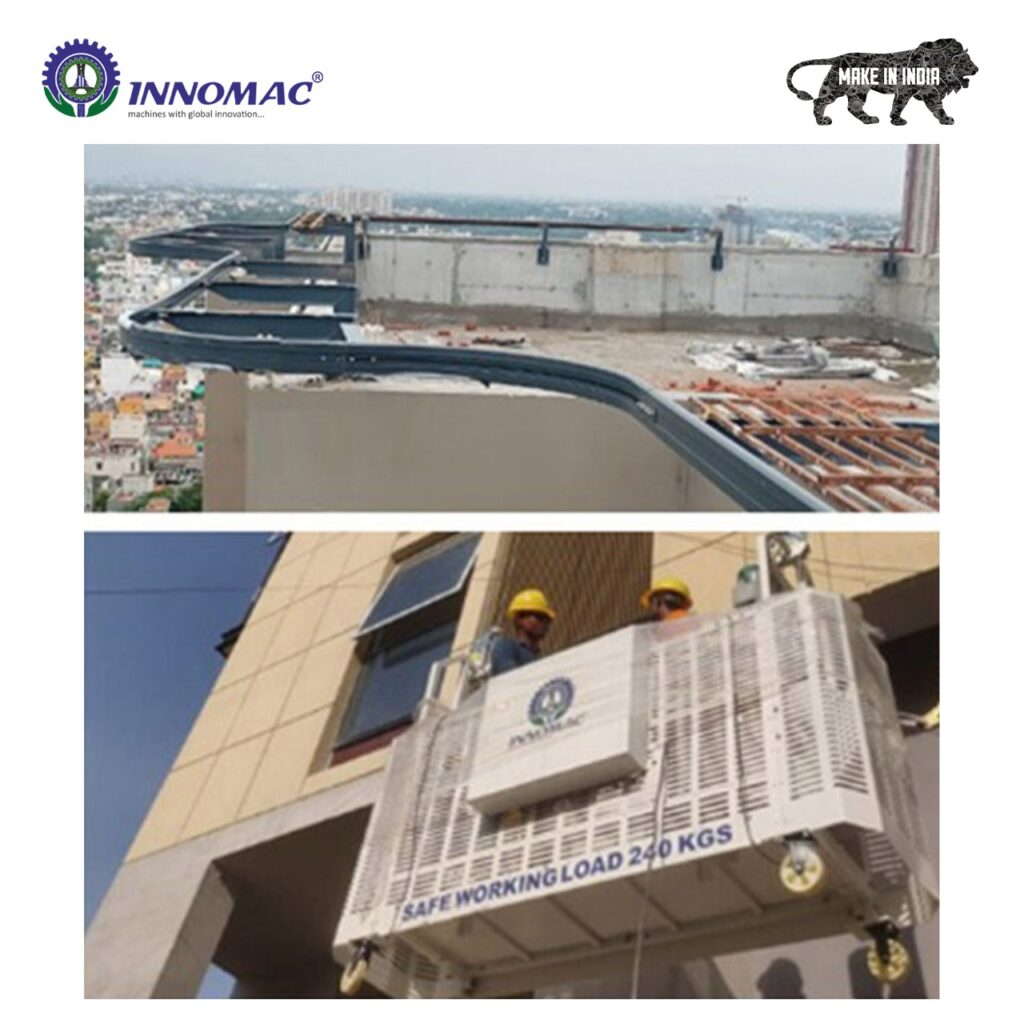

Looking for a reliable Passenger Hoist in Bangalore? Passenger hoists are essential for safely transporting workers and materials to different levels of high-rise construction sites. In Bangalore’s booming construction sector, top suppliers and rental companies offer high-performance passenger hoists that ensure smooth vertical movement, enhanced safety, and operational efficiency. These hoists are built with advanced safety features like overload protection, emergency brakes, and strong cage enclosures to meet site-specific requirements. Whether for short-term projects or long-term infrastructure development, you can find cost-effective and certified passenger hoist solutions in Bangalore that comply with industry standards and improve site productivity.

When it comes to choosing a dependable passenger hoist in Bangalore, top suppliers offer a wide range of models designed to meet varying load capacities and height requirements. These hoists are commonly used in residential, commercial, and infrastructure projects across the city. Leading vendors ensure their equipment is sourced from reputed brands and rigorously tested for safety and performance. If you’re looking for durable, easy-to-install, and low-maintenance hoists, Bangalore-based suppliers provide both sales and service support to meet your project deadlines effectively.

Modern passenger hoists in Bangalore are equipped with advanced safety and automation features that make vertical transportation efficient and secure. With load capacities ranging from 1 to 2 tons and customizable cage dimensions, these hoists are ideal for transporting both personnel and construction materials. Features like anti-fall devices, limit switches, and interlock systems enhance the safety quotient on-site. Additionally, many hoists come with energy-efficient motors and robust structural design to withstand tough site conditions, making them a vital asset for any large-scale construction activity.

INNOMAC PASSENGER CUM

MATERIAL HOIST

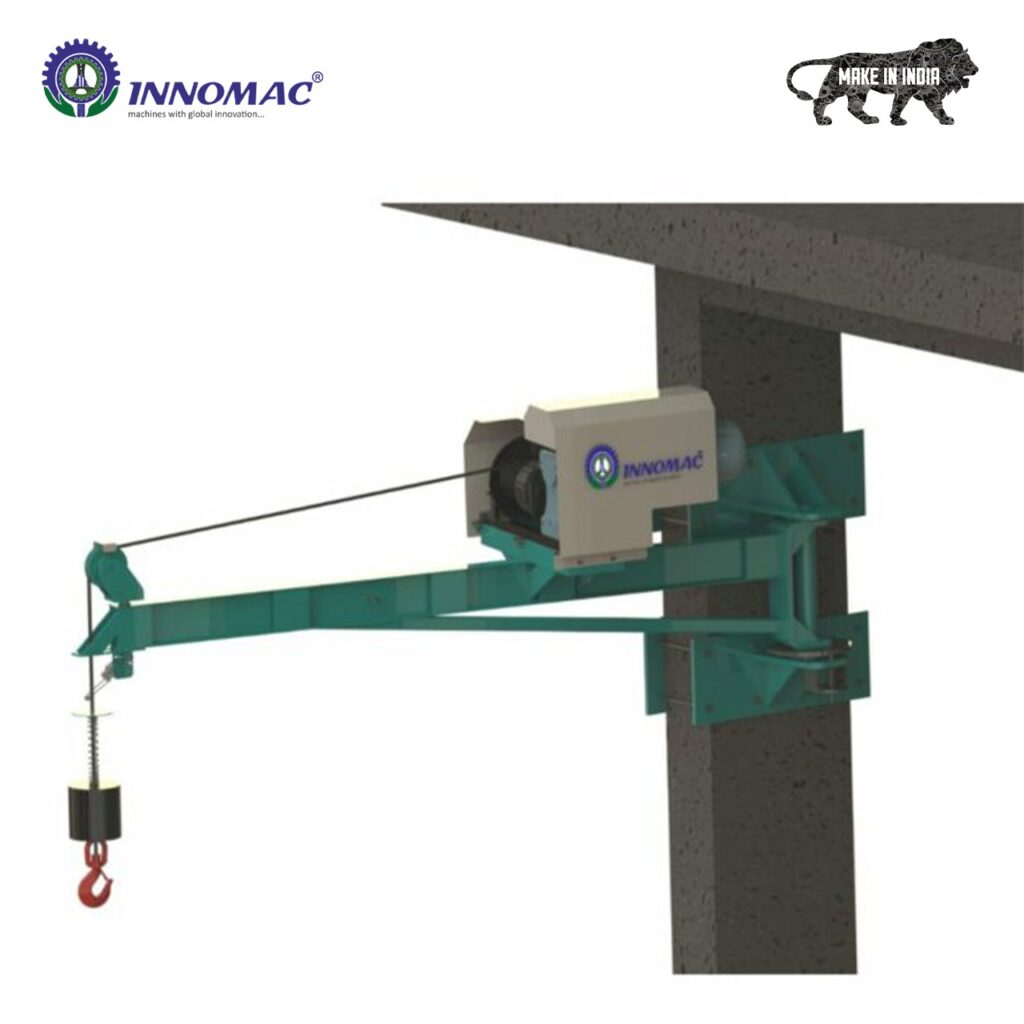

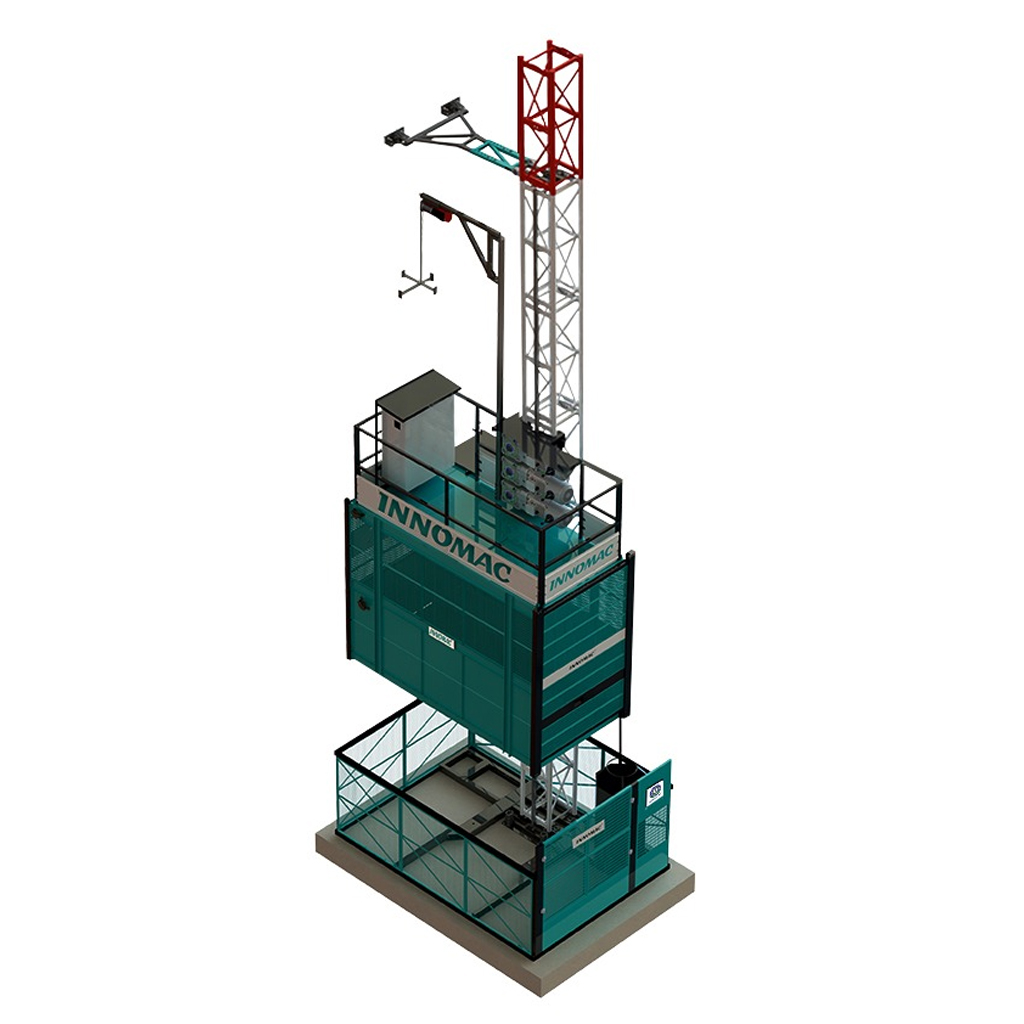

INNOMAC Passenger cum material hoist, model: IPM-200 is an 100% make in India concept product designed to lift 2000 kg . It is the most robust, efficient, reliable and Safest PM Hoist for construction sites for various construction mounting applications and construction activities.

Passenger cum material Hoists are designed with FEA Compliant parts and assemblies to meet design robustness and reliability need of the equipment. The CNC Punching, bending ,CO welding operations in the specific dies and fixtures makes the unit perfect and produce reduced noise and vibrations.

The Modern electric system of the LED Lighting, fan, the smooth operations of the machine with VFD drive, sliding door system, joystick operations with the option of overload cut off, floor selector and emergency switch panel make the operator more comfortable and confident to use the machine and remain fatigue free.

ERGONOMIC DESIGN

Passenger cum materials Hoists are designed with FEA Compliant parts and assemblies to meet design robustness and reliability need of the equipment. The CNC Punching, bending ,CO welding operations in the specific dies and fixtures makes the unit perfect and produce reduced noise and vibrations.

The Modern electric system of the LED Lighting, fan, the smooth operations of the machine with VFD drive, sliding door system, joystick operations with the option of overload cut off, floor selector and emergency switch panel make the operator more comfortable and confident to use the machine and remain fatigue free.