INNOMAC MATERIAL HOIST

INNOMAC MATERIAL HOIST

It’s Truly multifunctional

Build More.!

Build Fast..!!

Build Safe…!!!

MODELS: IMH1000 & IMH1500

(IN COMPLIANCE WITH IS12466:2012)

SAFETY FEATURES

- Emergency cut off switch

- Power fail safe brake motor

- Mechanical free fall arrester lock

- Upper limit switch

- Lower limit switch

- Fully guarded drive unit

INNOMAC Material Hoist is a Rugged designed system for easy vertical material movement in construction sites offering

best in class features, reliability and safety. The drive system of the machine is with latest technology In-line gear box and

energy efficient reliable S-4 Duty Brake Motor. The built-in brake system in the motor provides safety by self-locking during power

failure, the Machine also has a mechanical safety lock in case of any rope slips / rope damage.

STANDARD ACCESSORIES :

INNOMAC CONSTRUCTION LIFT

INNOMAC CONSTRUCTION LIFT

Innomac Construction Lifts are robust in design having best in the segment features like high Operating

speed, 360° Rotation, Safety limit switch, rigid drive system and etc.

The structure and major components are designed with FEA to meet higher reliability of the equipment.

STANDARD ACCESSORIES :

IE2 Brake Motors: Innomac is providing rugged made-in-India and energy efficient IE-2 motors for longer life and higher energy efficiency. The electro-mechanical built-in brake systems ensures safety during power failures.

Robust Gear Box: This machine comes with a heavy-duty speed reduction gear box directly coupled to the rope drum, thus eliminating any belt drives.

1.6 metre long Boom: This equipment provides a very long boom of 1.6 metre with 500 kg capacity with a very compact footprint which is best in its segment.

Safety limit switch: All models comes with a safety top limit switch as a standard option with auto motor cut-off, in case of operator missing to switching it off on time.

Counter weight tray: The machine can be attached to two rugged counter weigh trays which are specially designed to take 4” or 6” concrete blocks.

Counterweight bucket: Apart from the machine counterweight system we also provide a boom counterweight system to balance the weight of the boom.

Pendent operation control: Machine is controlled by a relay based control panel which auto cuts off in case of overload, over traverse. The operator buttons are mounted through the remote pendent for easy of operation.

Tool Box: Innomac has introduced tool box in mini-lift for the first time in the industry, which can be used to store tools or any ready spare parts.

Winch Motor Cover: The machine comes with fully guarded motor and gear box which provides safety and protection.

FEA complaint: The machine is tested and verified both practically and by FEA software to get the best performance of the machine.

OPTIONAL ACCESSORIES :

Brick handling tray : Specially designed, mesh covered tray for lifting concrete blocks in construction sites.

Sand/Concrete tray : Specially designed robust structure concrete tray with no leakage.

Load cell : This acts as a overload protection when the load crosses 500KG.

Counter Weight : Specially designed high grade concrete counter weight with steel enclosure and handle for longer life.

INNOMAC RM 800

INNOMAC RM 800

INNOMAC Launches the Robust and Top class

Reversible concrete mixture – IRM 800 with latest features.

Discharge Chute: Innomac is providing rotatable discharge chute for the first time in IRM800 to assist the operator in controlling the Flow direction of discharged concrete mix

Centralised Lubrication System: Machine is built with centralised lubrication system to reduce the efforts in lubricating all bearings periodically.

Auto Water flow control: System comes with provision of both manual & Auto control of water flow into the drum

Water Jet Gun: Innomac has introduced water jet gun to help the operator in cleaning the machine after work

Digital Weighing system: The machine comes with Load cell and digital display window with a provision of RS 232/ USB port and printer facility as an option Machine is powered by 3 Phase 10 HP

Ie2 motors Planetary Gear Box: Innomac introduced oil filled Planetary gear box in IRM800 which reduces power loss during transmission and eliminates maintenance risks

Admixture system: The machine comes with manual Ad-mixture pump with measuring scale on it, which helps users in controlling the required quantity of ad-mixture liquidIRM800 comes with 1, 2 & 3 bins along with Manual Jack levelling system

Hour Meter: Innomac is providing Hour meter in its Reversible mixer. This helps P&M team to monitor utilization and plan scheduled maintenance.

ROPE SUSPENDED PLATFORMS

ROPE SUSPENDED PLATFORMS

Rope Suspended Platforms range our machines as highly efficient, safe and durable with advanced features. Quality stands first for INNOMAC and our machines reflect it in every aspect.Our platforms are supplied with Hot Dip Galvanized of 80 to 100 micron, This helps no rusting, Avoids regular repainting and increases life of the structure.Module to Module Pin joint systems are provided for better and fast assembly.

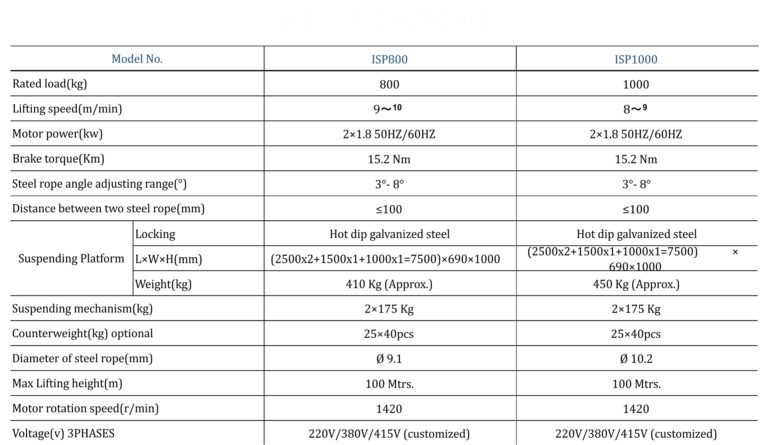

SPECIFICATION

Applications of Suspended Working Platform.

- Cleaning and maintaining of the exterior wall of highrise building.

- Painting, decoration and refurbishing of exterior walls.

- Installation projects and other construction working of outer walls of high-rise building.

- Aerial working of ship, large tower, bridge, dams and large chimneys.

- Install and maintain for high-rise building elevator hoist way, shipbuilding industry, seagoing vessel, warships welding maintain.

The conventional Fastener joints are avoided to eliminate damages of threads, Nuts and decrease of operating cost.The pins are locked to the platform body through steel wires for longer usage to avoid misplacement.

Advantages of Suspended Working Platform

- Suspended working platforms are designed and constructed in modular form so, it can be mounted in any size from 1 – 7.5 meters.

- The connection of the individual parts of the structure in each unit is made with nuts and bolts.

- The suspended platform is equipped with wheels for easy movement around the construction site.

- The working platform has bolt type and pin type.

- Modular design. Easy to disassemble, assemble operate and maintain.

- Lifting height can be adjusted according to requirement (Maximum 100 Meters).

BAR CUTTING MACHINE

BAR CUTTING MACHINE

Bar Cutting Machines ranges our machines as highly efficient, safe and durable with advanced features. Quality stands first for INNOMAC and our machines reflect it in every aspect.

This manual provides information for the following model(s) in the Bar Cutting machine range:

1.ICM42 2.ICM 52 3. ICM 55

This manual is arranged to give you a good understanding of the machine and its safe operation. It also contains maintenance information and specification data. Read this manual from front to back before using the machine for the first time. Particular attention must be given to all the safety aspects of operating and maintaining the machine.

SPECIFICATION

| Machine Model | Motor capacity | Stroke / min | Overall Weight (kg) | Oil Volume (ltr) | Overall Size (mm) |

| ICM 42 | 3.7kW/5.0HP 2900 RPM | 87.5 | 449 | 4.5 | 1050 X 380 X 814 |

| ICM 52 | 3.7kW/5.0HP 2900 RPM | 58.5 | 574 | 5 | 1154 X 532 X 944 |

| ICM 55 | 5.0kW/7.5HP 2900 RPM | 59.0 | 810 | 7 | 1215 X 720 X 1130 |

CAPACITY CHART

Cast wheels are provided as a default option with all variants which aid is easy movement of machine at site

FEATURES OF BAR BENDING MACHINES

All critical parts of the machine are designed and tested by FEA software to achieve best performance.

Tool Box: Innomac is introducing toolbox in cutting machine for the first time in the industry which can be used to store tools and spares like Allen keyset, Blades, etc securely.

Hour Meter: Innomac is introducing Hour meter for the first time in cutting and bending machinery. This helps P&M team to monitor machine utilization and plan scheduled maintenance.

All models are provided with specious custom mode DoL starter with built in additional safety for Over and under voltage protection and reverse rotation prevention.

Ergonomically designed hand lever is easy to operate using operator body weight and needs less effort and safe operation from front side,

Cast wheels are provided as a default option with all variants which aid is easy movement of machine at site,

All gears are precision helical gears which are smoother, quieter and more efficient than primitive spur gear design.

All models come with motors of uniblock heavy-duty castiron body which provide more robustness than aluminum motors.

All models come with safety plate with handle interlock, which provide additional safety as the operating level will be locked when safety plate is in open position.

BAR BENDING MACHINE

BAR BENDING MACHINE

SPECIFICATION

| Machine Model | Motor capacity | Bend wheel RPM | Overall weight (Kg) | Overall Size LxBxH (mm) | Bend Wheel Dia (mm) | Max Bend Radius | Bushes Supplied | Pins Supplied |

| IBM 42 | 3.7kW/5.0HP 1440 RPM | 9.05 | 329 | 805x710x963 | 350 | 4D for ᶲ25, | ᶲ60, ᶲ70, ᶲ100 | – |

| 3D for ᶲ32 | ||||||||

| IBM 52 | 4.0kW/5.5HP 1440 RPM | 9.05 | 410 | 868x950x963 | 426 | 5D for ᶲ32, | ᶲ60, ᶲ70, ᶲ100 | – |

| 4D for ᶲ36 | ||||||||

| IBM 55 | 5.0kW/7.5HP 1440 RPM | 9.05 | 583 | 990x950x1095 | 500 | 6D for ᶲ36, | ᶲ60, ᶲ70, ᶲ100 | – |

CAPACITY CHART

Maintenance free Electrical Braking system.

FEATURES OF BAR BENDING MACHINES

- Hour Meter: Innomac is introducing Hour meter for the first time in cutting and bending machinery. This helps P&M team to monitor machine utilization and plan scheduled maintenance.

- 4 Pre-set Angles: The machine is supplied with 4 preset angles (30, 45, 90, 180)

- PLC control system: Machine is controlled by a PLC instead of traditional relay system for trouble free operation.

- PLC panel placed on operator side for ease of serviceability.

- Maintenance free Electrical Braking system.

- Imported fully enclosed IP55 foot pedal.

- Moly Grease filled planetary gear box – Lubricated for life.

- Utility tray: Machine door encompasses a tray which can be highly useful for operator to store drawings and other ready reference documents.

- Rigid sliding block with V-guide provides more ruggedness.

- Completely powder coated machine body for better protection and aesthetics.

- All pins and bushes with Electro nickel plating for better protection.

- Rigid and easily accessible Grouting legs for easy grouting and better machine rigidity.

- Wider lifting lugs for ease of operation.